Unveiling the Magic: Inside the Screen Printing Process of Bringing Your Designs to Life

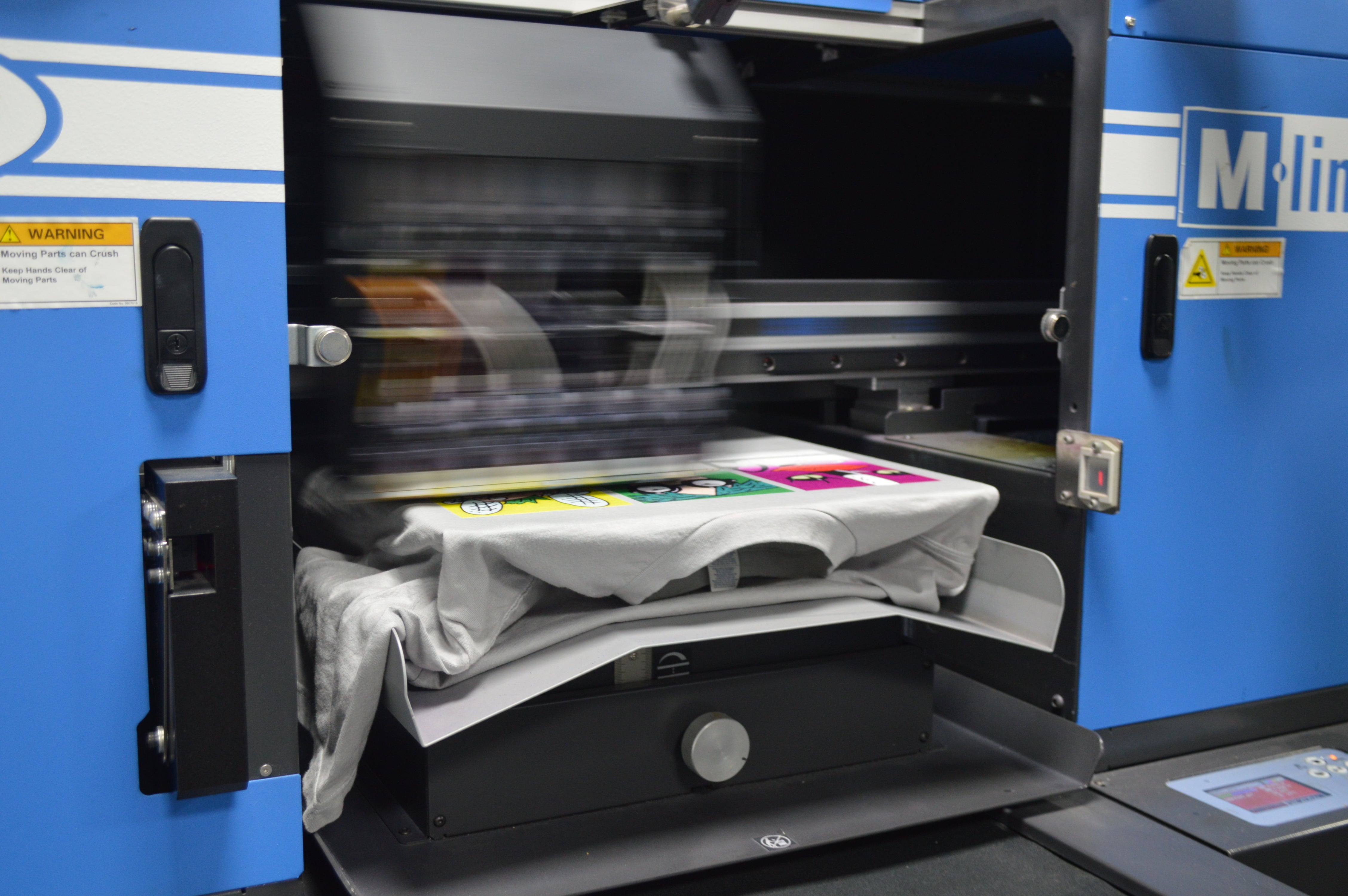

Have you ever wondered how your favorite t-shirts are made with such precision and detail? It’s all thanks to the screen printing process. At Factory1, we specialize in producing high-quality prints using this technique, which involves transferring ink onto garments through a finely woven mesh screen.

The screen printing process starts with creating a stencil of your design on a mesh screen. Ink is then applied to the screen, and a squeegee is used to press the ink through the finer mesh areas onto the garment. Each color requires a separate screen, which is layered one on top of the other until the final design is complete. We have perfected this process, ensuring that your custom t-shirts are produced with expert precision and care.

There’s something special about being able to print your own t-shirts, and we offer just that. With our state-of-the-art equipment and experienced team of professionals, we can help bring your designs to life through the screen printing process. Whether it’s for your sports team, company, or personal use, we’ll work with you every step of the way to ensure that your t-shirts are produced to your exact specifications.

Preparing Your Design for Screen Printing

Before your artwork can be printed on a t-shirt by screen printing process, it needs to go through a preparation process that will ensure that the final product meets your requirements. Here are some steps to follow when preparing your design for screen printing:

-

Choose the Right Design Software: To get the best results from the screen printing process, it is important to choose a design software that is compatible with the printers. Some of the popular design software for t-shirt printing include Adobe Photoshop and Illustrator. You may opt to design your artwork using the software yourself, or you can use a graphic designer to aid in the process.

-

Determine the Colors: When preparing your design for screen printing, you must determine the number of colors you will be using. Each color in a design requires its separate film and screen, so additional colors will increase the cost of production. Choosing the right colors and the right color combinations is key to ensuring that your final product is of high quality.

-

Finishing Options: After determining the design and colors, choose from the many finishing options available to finalize your design.

- Submit Your Artwork: Once you’ve completed the design, you need to submit it to Factory1 for a review. The review process will ensure that your design meets all the necessary requirements to ensure compatibility with their screen printing process. If adjustments need to be made, our graphic designers will advise you accordingly.

The screen printing process is an ideal way to print your own t-shirts. With the right preparation, you can produce clean, high-quality prints for your personal or professional needs.

Creating the Stencil for Your Design

Once we have the screens ready for your design, it’s time to create the stencil that will be used for the printing process. We use a photosensitive emulsion to transfer the design onto the screen.

The process starts by coating the screens with the emulsion, which is a light-sensitive material that will harden when exposed to light. We then place the screens onto a light table where your designs, which have been printed on a transparent film, are placed on top of the screens. The screens and films are then exposed to a bright light, which causes the emulsion to harden everywhere except where your designs are placed on the screen.

After the screens are exposed to the light, we carefully rinse them with water, which removes the excess emulsion that didn’t harden, leaving a clean stencil of your design on the screen. We then dry the screens and are now ready to start printing your designs on your t-shirts!

It’s important to note that creating the stencil is a crucial step in the screen printing process, and it’s important to ensure that the stencil is free of any errors or imperfections.

Mixing and Applying the Ink

The ink mixing and application process is a crucial step in the screen printing process where your designs come to life. We take this process seriously as it affects the overall quality of the final product.

Here’s a breakdown of our ink mixing and application process:

-

Ink mixing: We use a specialized ink mixing system to ensure accurate pigment ratios and consistency. Our mixing system makes use of high-quality pigments, which provide rich, vibrant colors that last longer even after multiple washes.

-

Ink application: We use the screen printing technique, where ink is pushed through a series of stenciled screens to create your designs. Each color requires a separate screen, and our team carefully aligns each screen to ensure that your designs come out perfectly printed. We make use of automated equipment to ensure uniform ink application, which provides a clean and consistent print.

- Drying and curing: After printing, we send your garments through a high-temperature dryer to cure the ink and set it permanently. The curing process ensures that the print stays vivid even after repeated washes.

Quality Control Checks

Ensuring our customers receive the highest quality products is one of our top priorities here at Factory1. To achieve this, we have strict quality control measures throughout our screen printing process.

After printing, we perform a series of quality control checks to ensure that your t-shirt looks perfect. We inspect each garment for print quality, color accuracy, and any smudging or ghosting. We also conduct a pull test to ensure that the print adheres to the garment and won’t peel or crack after a few washes.

Finally, we conduct a visual inspection of the finished product before folding and packing it for delivery. We ensure that each t-shirt is of the highest quality and meets our standards before shipping it out to you.

At Factory1, we believe that our attention to detail and quality control measures set us apart from other screen printing companies. By partnering with us to print your own t-shirts, you can be confident that you will receive a high-quality product that meets your expectations.

Understanding the screen printing process is important for anyone looking to print their own t-shirts. By familiarizing yourself with the different stages of the process, you can ensure that you get the best possible results from your designs.

We hope that this article has provided useful information about the screen printing process and how your designs can come to life. Starting from creating the design, preparing the screens, making the stencils, and mixing the pigments for printing, every step is crucial in producing high-quality t-shirts.

Screen printing has a wide range of applications for both personal and commercial use, including smaller-scale projects like customizing t-shirts for special events or creating merchandise for your brand. With Factory1’s expertise, you can confidently print your own t-shirts with excellent quality and professionalism.

Whether you are an entrepreneur looking to make a name for your brand or simply want to immortalize your artwork on fabric, screen printing is a versatile and cost-effective method to achieve your goals. Explore the possibilities that this process has to offer and unleash your creativity in a whole new way with the help of Factory1.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.